The Product

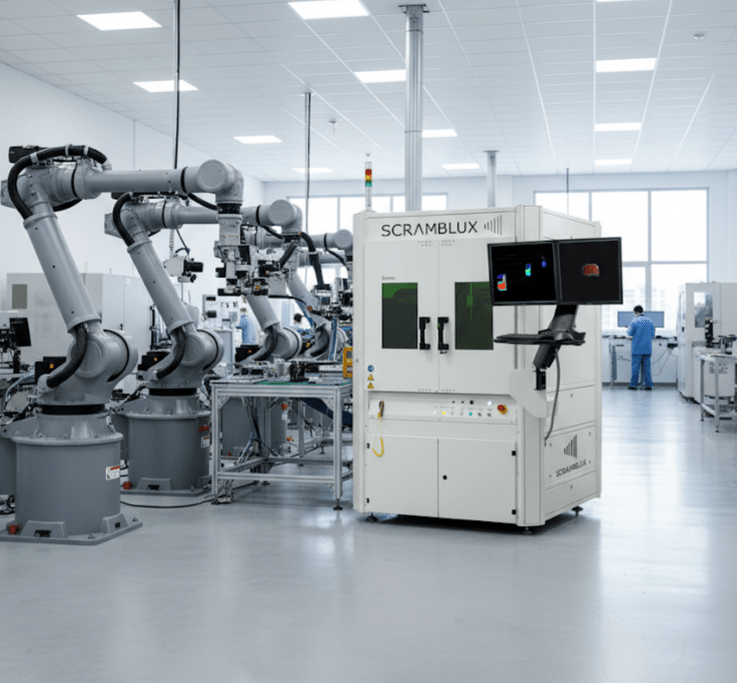

BeamScrambler

The BeamScrambler is an advanced optical measurement tool specifically designed for testing and calibrating LiDAR sensors across a wide range of performance parameters.

It offers our customers in production, during installation on vehicles and in the aftermarket validation a groundbreaking opportunity with its high-speed testing, exceptional measurement capabilities, compact footprint and flexibility.

Key features of the system

Compact footprint (≤ 2m²) and fully automated test system which can be integrated in production lines

Direct measurement of LiDAR (ToF, FMCW,…) key performance parameter in a single measurement system (Range, Resolution, Channel specific pointing, Eye Safety, Field of View, etc.)

Ultra-Fast (CT ≤ 20sec/LiDAR), measurement at multiple ranges at once

Testing under real-world environmental conditions (Snow, Rain, Fog, Splash, Dust and other performance limiting factors)

The LiDAR – a key enabling technology

LiDAR (Light Detection and Ranging) is a remote sensing technology that is critical for the development of fully autonomous vehicles and advanced driver-assistance systems (ADAS). It works by emitting rapid laser pulses and measuring the time it takes for the light to reflect off objects and return to the sensor. This “time-of-flight” data is used to calculate precise distances, generating a high-resolution, real-time 3D map of the surrounding environment known as a “point cloud.

“This rich, 3D environmental model is a primary input for a vehicle’s computational systems. The vehicle’s electronic control units (ECUs) analyze this point cloud to identify and track objects like pedestrians, vehicles, and obstacles, enabling critical decisions for navigation, collision avoidance, and path planning.

While pivotal for automomous vehicles, LiDAR’s applications are vast, extending to aerial mapping, robotics, urban planning, and environmental monitoring. The LiDAR market is experiencing explosive growth, with projections from various analysts suggesting it will grow from approximately 4.1billionin2024towellover8 billion by 2029, driven largely by its accelerating adoption in the automotive industry.

The Team

Simon Viets

Simon, who founded SCRAMBLUX in June 2022, has over 15 years of experience working in the mobile phone and automotive industries, with a specialization in optical metrology and micro-assembly. He holds a Diploma in Microsystems Engineering and has previously worked at TRIOPTICS, AEI (ASMPT) and ficonTEC.

Dr. Mirvais Yousefi

Mirvais, who joined SCRAMBLUX in June 2022, has over two decades of experience leading technology teams and establishing labs at top companies such as TNO, Huawei, and ficonTEC. He has a keen interest in technology, lasers, automation, and 3D imaging using sensor fusion.

The Partner

ELAS Technologies Investment GmbH

Lead-Investor

ELAS Technology Investment GmbH (ELAS) is a German-based but globally oriented financial investor, with Headquarters in Hamburg in the north of Germany. ELAS’ founders provide over 20 years of comprehensive experience in nurturing organizations and fostering growth and have already successfully identified multiple business opportunities in the photonics and supporting sectors. This includes, for example, ficonTEC Service GmbH, the leading supplier of production systems for photonic assembly and test, with leading-edge global customers in sectors such as telecom/datacom, automotive, LiDAR, satellite communications and more.

ficonTEC

Service GmbH

Automation Partner

ficonTEC is an innovative high-tech company that has rapidly established itself in a highly-specialized market. With continued growth and innovative development since 2001, they are the recognized market leader when it comes to automated assembly and testing of opto-electronic components and (hybrid) photonic devices.

The core team at ficonTEC consists primarily of development engineers from the specialist fields of optics and photonics, from electrical, mechanical and mechatronic engineering, as well as from software development. These developers are supported by experienced technicians possessing a wide variety of skills.

Leibniz University

Hanover – IPeG

Development Partner

The Institute of Product Development (IPeG) at Leibniz University Hanover is a research institution focused on optomechatronic devices and additive manufacturing.

The IPeG collaborates with industry partners to transfer research to application.

The Institutes research areas include digitalization in product development, additive manufacturing, mechatronic systems, robotics and automation, and sustainable product development.

Its main goal is to explore innovative solutions, advance technologies, and contribute to the education of professionals in product development.

About us…

SCRAMBLUX was established in 2022 in Hamburg, Germany as a reaction to the strong demand from the automotive industry for a compact and efficient LiDAR sensor test and calibration solution for mass production.

We did this by inventing a solution that mixes a patented optical instrument from 1817 with state-of-the art digital and AI technology to build a completely new and innovative instrument.

As founders, we have embraced the challenge of developing a unique, innovative and easy to use solution with the goal to revolutionize the testing and calibration for LiDAR sensors.

ELAS Technologies Investment GmbH, our seed investor, supported us at the outset of our journey, and in April 2023, we filed our first patent for the solution.

Contact us…

Your message has been sent

Funded Projects…

4D point cloud generator for lidar testing

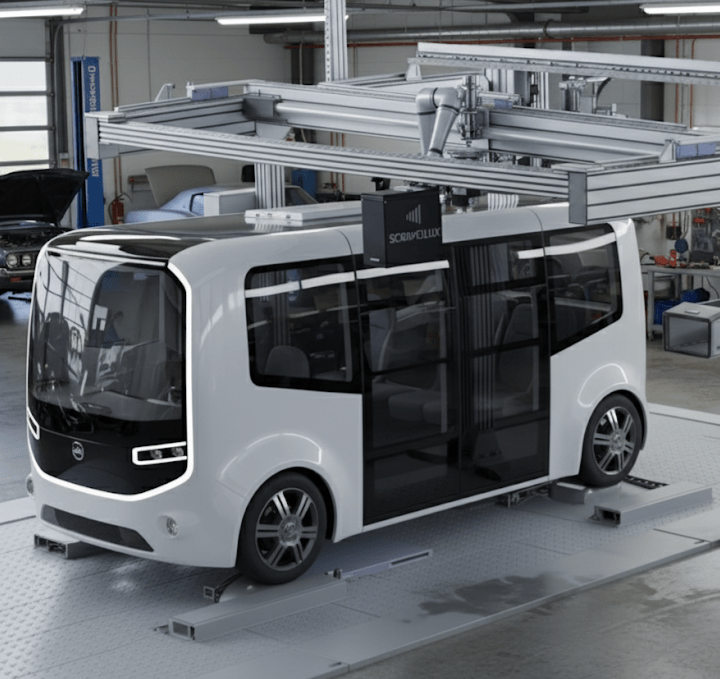

As autonomous mobility advances, the requirements for LiDAR sensors—the eyes of future vehicles—are becoming increasingly complex. To ensure safety and reliability, these sensors must not only measure distances but also correctly identify objects and vulnerable road users like pedestrians or cyclists in highly dynamic situations.

The Challenge

Currently, testing LiDAR perception stacks (the software responsible for object recognition) requires either massive physical test fields or relies on purely virtual simulations that may not fully reflect real-world sensor behavior. Conventional compact test setups are often limited to static targets, making them unsuitable for validating complex, moving scenarios.

Our Solution

In this project, Scramblux GmbH, together with Leibniz University Hannover and Hochschule Osnabrück, is developing a novel 4D Point Cloud Generator. This system functions similarly to a sophisticated “virtual reality” display for LiDAR sensors6.

By utilizing advanced optical technologies the system can generate synthetic point clouds that the sensor perceives as real, moving, three-dimensional environments. This allows for the direct translation of scenarios from simulation software into physical optical signals, enabling realistic, repeatable, and compact testing of LiDAR perception under dynamic conditions.

Key Objectives

- Development of an over-the-air test system for testing LiDAR perception stacks.

- Creation of dynamic, spatially deep scenarios in a compact laboratory setup.

- Seamless integration with established simulation software for automated validation.

Project Partners

- Scramblux GmbH: Project lead, system architecture, and commercialization.

- Leibniz Universität Hannover (IPeG): Expertise in optomechatronic systems and optical component development.

- Hochschule Osnabrück (Labor für Mikro- und Optoelektronik): Validation, simulation environments, and sensor system testing.

Project Duration: September 2025 – August 2027

You must be logged in to post a comment.